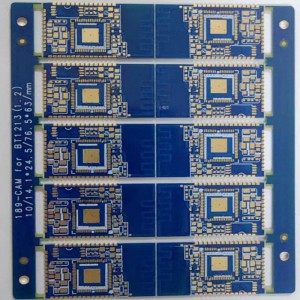

Pcb prototype pcb fabrication blue solder mask plated half-holes

Tlhaloso ea Sehlahisoa:

| Boitsebiso ba Motheo: | FR4 TG140 |

| Botenya ba PCB: | 1.0+/-10% limilimithara |

| Palo ea Lera: | 2L |

| Botenya ba Koporo: | 1/1 oz |

| Phekolo ea sefahleho: | ENIG 2U” |

| Mask ea solder: | Boputsoa bo benyang |

| Silkscreen: | Bosoeu |

| Ts'ebetso e khethehileng: | Pth halofo ea masoba mathōkong |

Kopo

PCB halofo-soba boto e bua ka ea bobeli ho cheka le sebopeho tshebetso ka mor'a hore lesoba la pele e phunngoa, 'me qetellong halofo ea lesoba metallized e boloketsoe. Sepheo ke ho tjheseletsa ka ho toba moeli oa lesoba ho ea moeling o ka sehloohong ho boloka lihokelo le sebaka, 'me hangata li hlaha lipotolohong tsa matšoao.

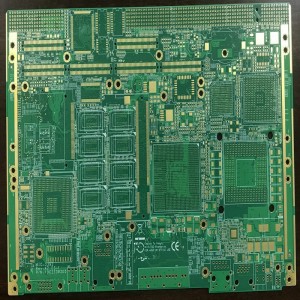

Hangata mapolanka a potoloho a halofo ea lesoba a sebelisoa bakeng sa ho kenya lisebelisoa tsa elektronike tse nang le lik'hemik'hale tse ngata, tse kang lisebelisoa tsa cellular, lioache tse bohlale, lisebelisoa tsa bongaka, lisebelisoa tsa molumo le video, joalo-joalo Li nolofalletsa ho ba le sekhahla se phahameng sa potoloho le mekhoa e mengata ea ho hokahanya, ho etsa hore lisebelisoa tsa elektronike li fokotsehe, li be bobebe le tse sebetsang hantle.

Sekoti se sengata se sekoti lipheletsong tsa PCB ke e 'ngoe ea lintho tse sebelisoang hangata molemong oa tlhahiso ea PCB,' me mosebetsi oa eona o ka sehloohong ke ho lokisa PCB. Ts'ebetsong ea tlhahiso ea boto ea PCB, ka ho siea likoti tse halofo maemong a itseng moeling oa boto ea PCB, boto ea PCB e ka ts'oaroa ka sesebelisoa kapa ntlo e nang le likurufu. Ka nako e ts'oanang, nakong ea ts'ebetso ea kopano ea boto ea PCB, lesoba la halofo le boetse le thusa ho beha le ho hokahanya boto ea PCB ho netefatsa ho nepahala le botsitso ba sehlahisoa sa ho qetela.

Sekoti sa halofo se kenngoeng ka lehlakoreng la boto ea potoloho ke ho ntlafatsa ts'episo ea khokahanyo ea lehlakore la boto. Hangata, ka mor'a hore boto ea potoloho e hatisitsoeng (PCB) e fokotsoe, lesela le pepesitsoeng la koporo moeling le tla pepesoa, le atisang ho ba le oxidation le corrosion. E le ho rarolla bothata bona, lera koporo hangata tlotsitsoe ka lera sireletsang ka electroplating bohale ba boto ka lesoba halofo ho ntlafatsa khanyetso lona oxidation le ho hanyetsa kutu, 'me e ka boela eketsa sebaka tjheseletsa le ho ntlafatsa ho tšepahala ha kgokelo.

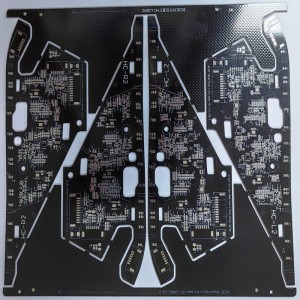

Nakong ea ts'ebetso, mokhoa oa ho laola boleng ba sehlahisoa ka mor'a ho etsa masoba a semi-metallized moeling oa boto, joalo ka meutloa ea koporo leboteng la lesoba, joalo-joalo, esale e le bothata bo boima ts'ebetsong ea ts'ebetso. Bakeng sa mofuta ona oa boto e nang le mokoloko o feletseng oa likoti tse entsoeng ka semi-metallized The PCB board e tšoauoa ka bophara bo batlang bo le bonyenyane ba lesoba, 'me e sebelisoa haholo bakeng sa boto ea morali oa boto ea' mè. Ka masoba ana, e cheselitsoe hammoho le boto ea 'mè le lithakhisa tsa likarolo. Ha ho soasoa, ho tla lebisa ho solder e fokolang, ho soasoa ka bohata, le potoloho e khuts'oane ea borokho lipakeng tsa likhoele tse peli.

FAQs

Ho ka 'na ha e-ba molemo ho beha likoti tse koahetsoeng (PTH) moeling oa boto. Mohlala ha o batla ho solder li-PCB tse peli ho tse ling ka sekhutlo sa 90 ° kapa ha u solla PCB ho casing ea tšepe.

Ka mohlala, motsoako oa li-module tse rarahaneng tsa microcontroler tse nang le li-PCB tse tloaelehileng, tse entsoeng ka bomong.Lisebelisoa tse ling ke ponts'o, HF kapa li-module tsa ceramic tse rekisetsoang boto ea potoloho e hatisitsoeng.

Drilling- plated through hole (PTH) - panel plating - image transfer - pattern plating -pth half hole- striping - etching - solder mask - silkscreen - surface treatment.

1.Diameter ≥0.6MM;

2.The sebaka se pakeng tsa lesoba bohale ≥0.6MM;

3. Bophara ba reng etching hloka 0.25mm;

Half-hole ke ts'ebetso e khethehileng. E le ho etsa bonnete ba hore ho na le koporo ka mokoting, e tlameha ho sila pele pele e tšela koporo. PCB e akaretsang halofo ea lesoba e nyane haholo, kahoo litšenyehelo tsa eona li theko e boima ho feta PCB e tloaelehileng.