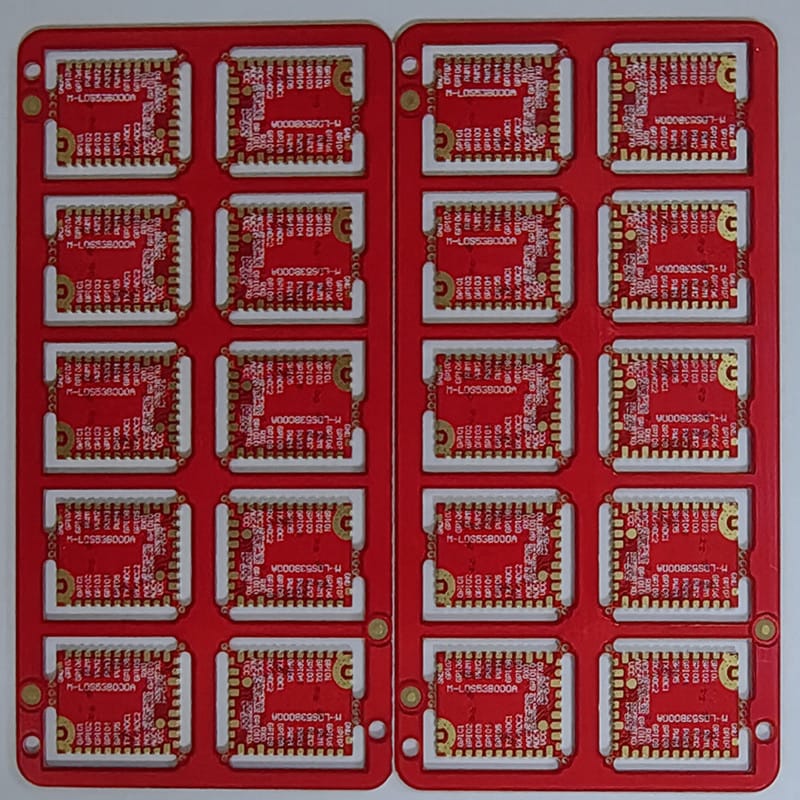

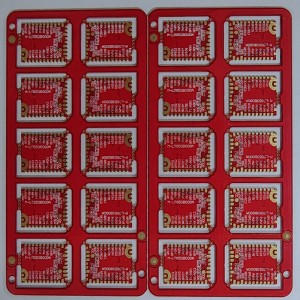

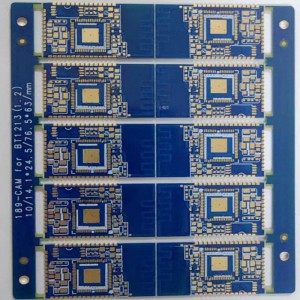

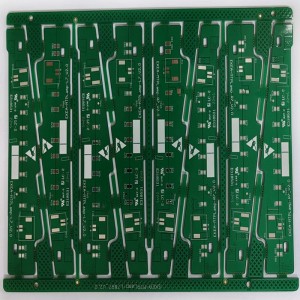

Prototype e hatisitsoeng liboto tsa potoloho RED solder maske likoti tse castellated

Tlhaloso ea Sehlahisoa:

| Boitsebiso ba Motheo: | FR4 TG140 |

| Botenya ba PCB: | 1.0+/-10% limilimithara |

| Palo ea Lera: | 4L |

| Botenya ba Koporo: | 1/1/1/1 oz |

| Phekolo ea sefahleho: | ENIG 2U” |

| Mask ea solder: | Bofubelu bo benyang |

| Silkscreen: | Bosoeu |

| Ts'ebetso e khethehileng: | Pth halofo masoba ka mathōko |

Kopo

Mekhoa ea ho etsa li-half holes tse petelitsoeng ke:

1. Etsa lesoba le lehlakoreng le halofo ka sesebelisoa sa ho itšeha habeli se nang le sebopeho sa V.

2. Boro ea bobeli e eketsa masoba lehlakoreng la lesoba, e tlosa letlalo la koporo esale pele, e fokotsa li-burrs, 'me e sebelisa li-groove cutters ho e-na le li-drill ho ntlafatsa lebelo le ho theoha.

3. Kenya koporo ho electroplate substrate, e le hore lera la koporo e electroplated leboteng lesoba lesoba le chitja ka bohale ba boto.

4. Tlhahiso ea potoloho e ka ntle ea lera ka mor'a lamination, ho pepeseha, le ntshetsopele ya substrate ka tatellano, substrate e tlas'a bobeli koporo plating le tin plating, e le hore lera koporo leboteng lesoba lesoba le chitja ka bohale ba boto e teteaneng 'me lera koporo e koahetsoeng ka ho koahetsoe ke lesela la thini bakeng sa ho hanyetsa kutu;

5. Ho etsa halofo ea lesoba ho khaola lesoba le pota-potileng moeling oa boto ka halofo ho etsa lesoba la halofo;

6. Mohato oa ho tlosa filimi, filimi e khahlanong le electroplating e hatelitsoeng nakong ea ts'ebetso ea ho hatisa filimi e tlosoa;

7. Etching substrate e ngotsoe, 'me koporo e pepeneneng holim'a lera le ka ntle la substrate e tlosoa ka ho etching;

8. Letlapa le hlobolang substrate le ntšoa ka thini, e le hore lesela le leboteng la lesoba le ka tlosoa, 'me lera la koporo leboteng la lesoba la halofo le pepesitsoe.

9. Ka mor'a ho theha, sebelisa tepi e khubelu ho khomarela liboto tsa lihlopha hammoho, 'me u tlose li-burrs ka mohala oa alkaline etching.

10. Ka mor'a koporo ea bobeli ea koporo le tin plating holim'a substrate, lesoba le pota-potileng moeling oa boto le khaoloa ka halofo ho etsa lesoba la halofo, hobane lera la koporo la lerako la sekoti le koahetsoe ke lera la thini, 'me lera la koporo la lerako la sekoti le senyehile ka ho feletseng le lera la koporo la lera le ka ntle la lera le ka ntle la substrate le ka thibela ho kopanya ka matla holim'a lera la koporo. lerako la lesoba ho tloha ha le huloa kapa ho roala ha koporo ha seha;

11. Ka mor'a ho etsa halofo ea lesoba ho phethoa, filimi e tlosoa ebe e kenngoa, e le hore bokaholimo ba koporo bo se ke ba e-ba le oxidized, ka katleho ho qoba ho etsahala ha koporo e setseng kapa esita le potoloho e khutšoanyane, le ho ntlafatsa tekanyo ea lihlahisoa tsa boto ea potoloho ea metallized halofo ea lesoba la PCB.

FAQs

Sekoti se entsoeng ka halofo kapa sekontiri se entsoeng ka setempe, ke moeli o bōpehileng joaloka setempe ka ho seha ka halofo holim'a kemiso. Plated half-hole ke boemo bo holimo ba mathōko a petelitsoeng bakeng sa liboto tsa potoloho tse hatisitsoeng, tseo hangata li sebelisetsoang likhokahano tsa boto ho ea ho boto.

Via e sebelisoa e le khokahanyo pakeng tsa likarolo tsa koporo ho PCB ha PTH e atisa ho etsoa e kholo ho feta vias 'me e sebelisoa e le lesoba le pota-potiloeng bakeng sa ho amoheloa ha likaroloana - tse kang li-resistors tse seng tsa SMT, li-capacitor, le DIP sephutheloana sa IC. PTH e ka boela ea sebelisoa e le masoba bakeng sa ho hokahanya ha mochine ha vias e ka 'na ea se ke ea e-ba teng.

The plating holim'a likoti ke koporo, conductor, kahoo e lumella conductivity ea motlakase ho tsamaea ka boto. Li-non-plated ka likoti ha li na conductivity, kahoo haeba u li sebelisa, u ka ba le lipina tse molemo tsa koporo ka lehlakoreng le leng la boto.

Ho na le mefuta ea 3 ea likoti ho PCB, Plated through Hole (PTH), Non-Plated through Hole (NPTH) le Via Holes, tsena ha lia lokela ho ferekanngoa le Slots kapa Cut-outs.

Ho tsoa maemong a IPC, ke +/-0.08mm bakeng sa pth, le +/-0.05mm bakeng sa npth.